We ensure the smooth operation of industrial enterprises

The subtitle

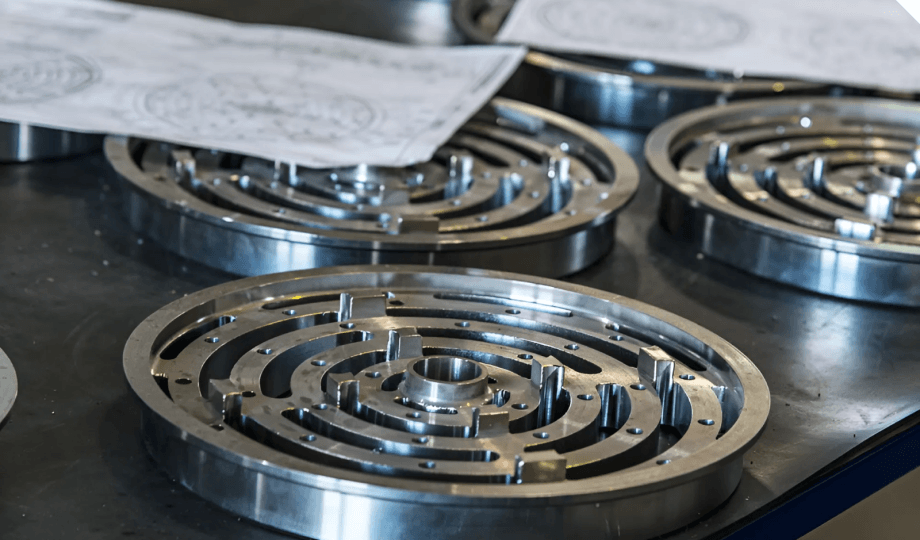

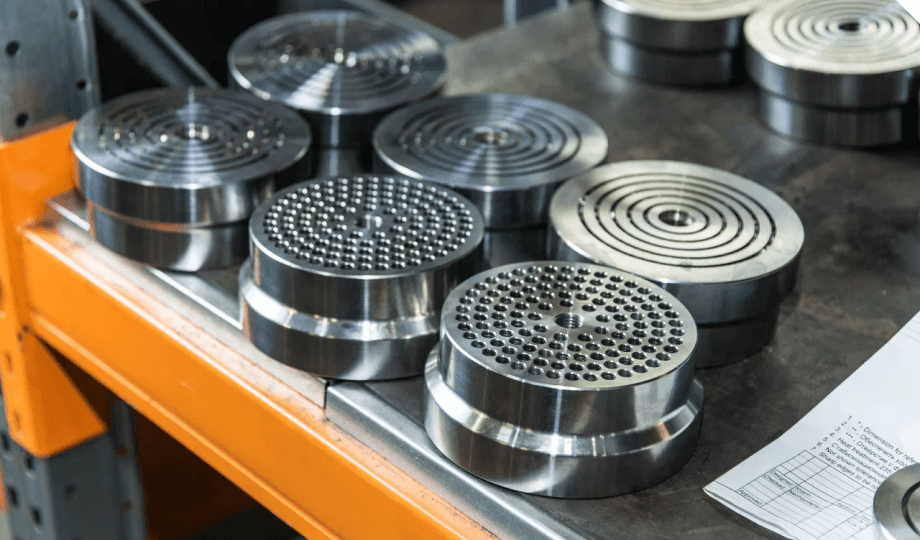

In the face of ever—increasing industry demands for equipment efficiency and reliability, AGV Compressor Solutions holds a leading position in the market of components for reciprocating compressors and gas piston engines. For more than 15 years of its history, AGV has not only established itself as a reliable manufacturer of high-quality spare parts, but also as a professional service partner for the largest enterprises of the fuel and energy complex. AGV serially produces spare parts for reciprocating compressors, as well as drive gas piston engines, has proven positive operating results and extensive reference. Valves, gas and oil seals, piston rings, sealing gaskets, AGV gas and gas mixing valves are of impeccable quality, in some applications superior to the original. The company has all the necessary technological and production capabilities for the production of rods and pistons for reciprocating compressors, parts of the cylinder heads of the GPD (valves, seats and valve guides). AGV specialists strive to offer the most complete line of high-quality spare parts and increase the life of the equipment. Thus, the company has developed a technology for manufacturing valve shut-off elements and stem seals from modern PEEK—type thermoplastics reinforced with glass and carbon fiber, previously offered only by foreign manufacturers. Its own development is also the application of a diamond-like coating on the metal parts of the nodes, which protects against abrasive wear. AGV uses DLC coating for use in particularly difficult operating conditions. An additional advantage is the full—cycle production, certified according to ISO 9001 and equipped with modern equipment.

Bulleted list

- AGV specialists

- Carbon fiber

- Self-developed

- AGV uses DLC coverage

- certified according to ISO 9001

Responsible partnership is the fundamental principle of AGV‘s operation, since the area of responsibility of the supplier of components for critical equipment is not limited to the supply of parts. The continuity of the production process depends on the integrity of the contractor and the quality of the products, the shutdown of which entails multimillion-dollar losses for the partner. The AGV team strives to ensure stable operation of the equipment, regardless of the complexity of the operating conditions. The in-depth technical expertise and long-term experience of the company‘s service engineers allows us to identify the causes in time and prevent possible problems in operation that lead to piston damage, stem breakage and other costly consequences. The AGV service department performs work of any complexity, including commissioning, major and emergency repairs, maintenance with constant presence at the facility.

Numbered list

- AGV specialists

- Carbon fiber

- Self-developed

- AGV uses DLC coverage

- Certified according to ISO 9001

Responsible partnership is the fundamental principle of AGV‘s operation, since the area of responsibility of the supplier of components for critical equipment is not limited to the supply of parts. The continuity of the production process depends on the integrity of the contractor and the quality of the products, the shutdown of which entails multimillion-dollar losses for the partner. The AGV team strives to ensure stable operation of the equipment, regardless of the complexity of the operating conditions. The in-depth technical expertise and long-term experience of the company‘s service engineers allows us to identify the causes in time and prevent possible problems in operation that lead to piston damage, stem breakage and other costly consequences. The AGV service department performs work of any complexity, including commissioning, major and emergency repairs, maintenance with constant presence at the facility.

Responsible partnership is the fundamental principle of AGV‘s operation, since the area of responsibility of the supplier of components for critical equipment is not limited to the supply of parts. The continuity of the production process depends on the integrity of the contractor and the quality of the products, the shutdown of which entails multimillion-dollar losses for the partner. The AGV team strives to ensure stable operation of the equipment, regardless of the complexity of the operating conditions. The in-depth technical expertise and long-term experience of the company‘s service engineers allows us to identify the causes in time and prevent possible problems in operation that lead to piston damage, stem breakage and other costly consequences. The AGV service department performs work of any complexity, including commissioning, major and emergency repairs, maintenance with constant presence at the facility. Customer orientation and high production culture allowed the company to build strong relationships with most enterprises of the Russian fuel and energy complex — Gazprom PJSC, Rosneft, Gazprom Neft, LUKOIL, Novatek, Sibur LLC, Rosenergoatom Concern JSC. AGV increases the cost—effectiveness of ensuring the smooth operation of the equipment.